MADFIG Projects

Ripper Gauge Trial

Soil amelioration is a key part of farming systems in Western Australia to overcome soil limitations to crop production. The removal of soil constraints such as compaction and water repellence through strategic tillage practices generally leads to increases in crop production in successive years.

One of the limitations that threatens the longevity of these benefits is that the soil can recompact over time following amelioration, often leading to levels higher than before amelioration. Currently, the solution is to repeat the deep ripping process every few years, with the period between deep ripping dependent on the soil type and amount of wheeled traffic on the paddock.

This is a costly repetitive process that may become unsustainable in the long term as soils become compacted to greater depths with successive tillage treatments and larger/heavier machinery. While there is a good network of demonstration sites established across the port zones of WA, there are a number of soil types where the benefit and longevity of soil amelioration practices are unknown.

The adoption of controlled traffic practices by growers is one tool that can potentially increase the longevity of soil ameliorative practices, by reducing soil compaction from wheel traffic by confining this to permanent wheel tracks across the paddock. However, the potential of controlled traffic practices to increase the longevity of amelioration treatments has only been evaluated on a narrow range of soil types.

This project aims to evaluate and demonstrate the benefit of soil amelioration across a wider range of soil types that are common to the WA grain growing region.

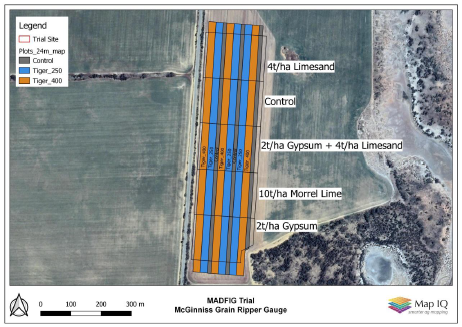

MADFIG and MapIQ, under contract through the West Midlands Group, set up at trial site North of Hines Hill. With the soil type predominately deep yellow sand, soil testing indicated acidic conditions to a depth of 80cms.

Two ripping depths (250mm and 400mm) and four different treatments were trialled. A 6mt Horsch Tiger was used at this site with the view that it would address both soil constraints present: compaction and the need to incorporate lime further into the soil profile.

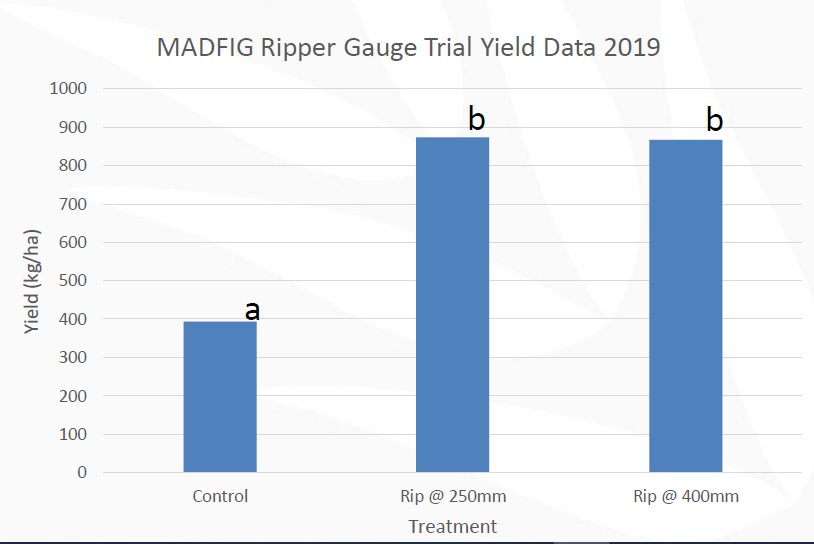

Graph 1. 2019 Canola Yield benefits by ripping

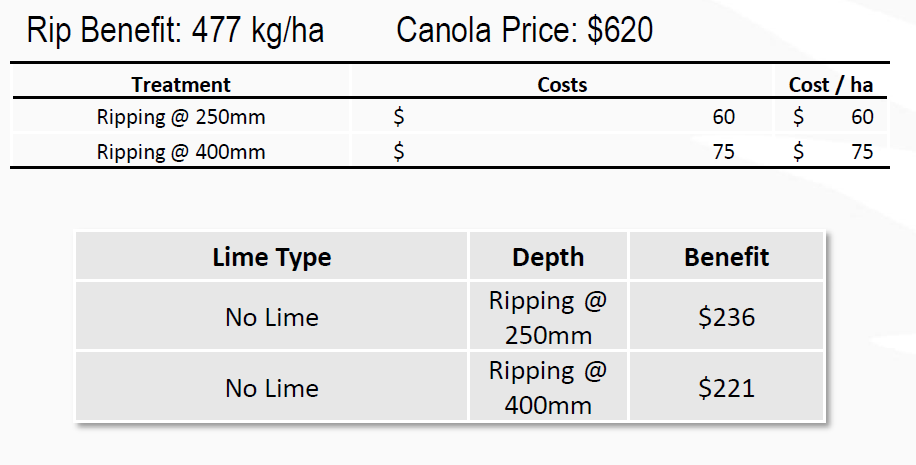

Costs associated with the deep ripping were estmated at $60/ha (@250mm depth) and $75/ha (@400mm depth). This was calculated at an estimated 5ha/hr using on average 66-74l of fuel per hour.

Both ripped treatments out yielded the control by more than 300% with a 592 and 585 kg/ha yield increase recorded for the 250m and 400mm treatments respectively.

This result is thought to show the removal of the hard pan has been successful and the plants were able to access more moisture and nutrients in the dry season. The results may also show that the 250mm ripping depth was able to remove the hardpan and the extra ripping to 400mm was not necessary. The soil compaction measurements did peak at 150-200mm which supports this theory.

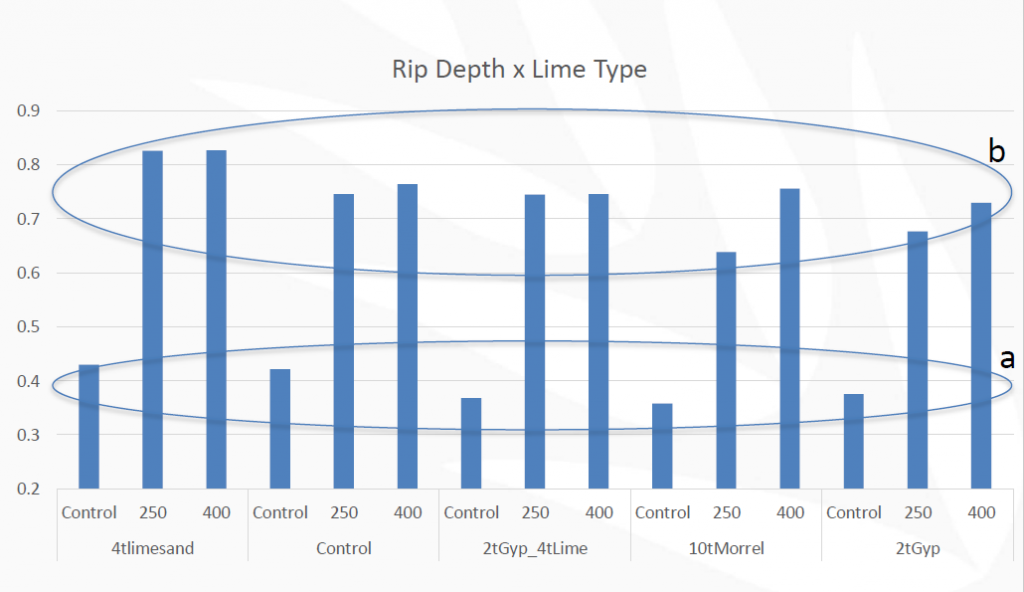

Figure 4. Trial results by treatment

It was interesting to note that there was no difference by lime types vs control (a) or any difference by lime type vs ripping depth (b).

Figure 5. Economic benefit of ripping

Trial results indicated that ripping had a positive 1 year return. There was a negative return where lime was used without ripping. Yield increases were attributed to a reduction in soil strength, soil pH increase and an increase in plant density.

There is one more year left at the trial site to further strengthen the findings and potential benefits shown through deep ripping.

Figure 1. MADFIG Ripper Gauge Trial Site

Figure 2. Soil core at the trial site

Figure 3. Deep Ripping treatments.

Become a Sponsor

MADFIG cannot succeed in it’s mission without the support of its valuable partners.

Annual sponsorships are available for purchase.